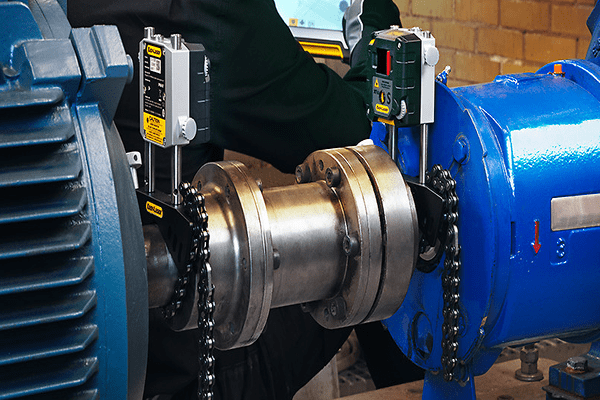

One of the most common problems with machines is poor alignment. Mis-alignment is one of the most common causes of severe oscillation of machines, drive axles and other components of a machine. Incorrect alignment and its consequences are responsible for over 50% of all malfunctions in rotating machines. The shafts, pulleys as well as a wide range of power transmission components in rotary machines need to be aligned. It is necessary for both single fans and motors – low and high-speed compressors, which have many refrigeration units. The purpose is to minimize wear (friction) caused by dynamic forces (forces/pressures) between the parts of a machine. Proper alignment eliminates problems such as high oscillation, energy loss, bearing damage, shaft failure, sealing failure, quality problems. This achieves greater overall resource savings with fewer spare parts and lower energy consumption. To this end our company workshop is equipped with laser axis alignment machines, with properly trained operating technicians.